Industrial automation is not new. But it is time to create a better modbus iot

integration for a

deeper understanding of your data and also manage your devices in a efficient way.

In the Industry 3.0, devices are managed in an isolated fashion. From late 1960s to early 19790

PLCs , DCS and few more ways to automate the simple process came into existence. In addition,

With the introduction of Modbus, programmers were able to mange them and automate a few of the

process in a localized fashion.

But these machines are still managed in the same isolated way in many industrial sectors.

However It is time to integrate them for a more productive outcome. Over the last few months, we

tried writing some code to integrate data received from Modbus/RTU into MQTT Broker. The

integration was very simple and straight. But One of the major challenge is the association of

the data we read from the Modbus Server to the actual spec as provided by the Manufacturer.

Modbus Protocol, a messaging structure developed by Modicon in 1979, is used to

establish

master-slave/client-server communication between smart devices. It is a de facto standard, truly

open and the most widely used network protocol in the field of industrial automation. It has

been implemented by hundreds of vendors on thousands of different devices to transfer

discrete/analogue I/O and route data between control devices.

Modbus is used in multiple master-slave applications to:

Modbus is used in a number of smart manufacturing solutions. But Modbus is not only an industrial protocol. Its benefits are also evident in the building, agriculture, transportation and energy applications.

We have used Raspberry Pi 3B+ for creating the gateway to gather the Modbus data and push data to AWS IoT Core (MQTT Broker).

We used the pymodbus python implementation of the Modbus IoT gateway. This will

query

the data

from the Modbus RTU PLC. Using the pymodbus implementation, you will be able to read and write

data into the the memory registers & Coils of your equipment.

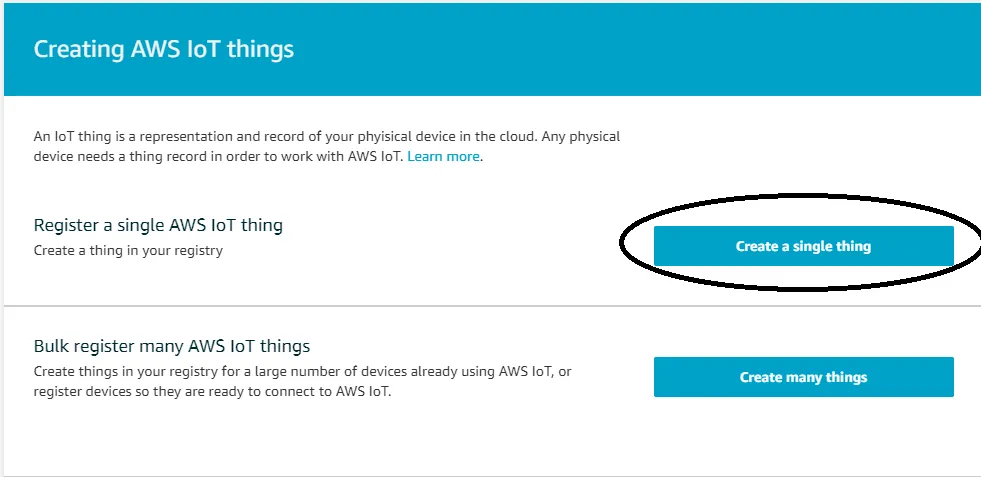

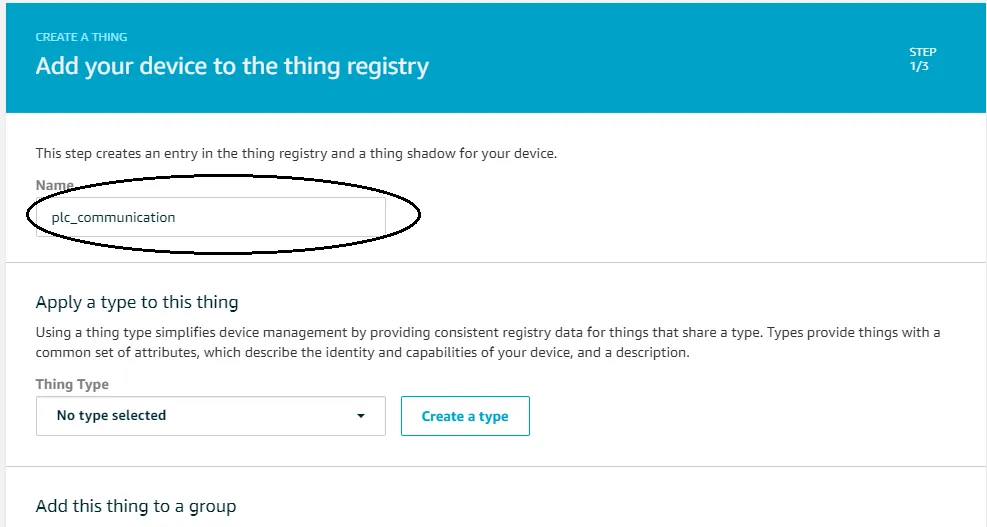

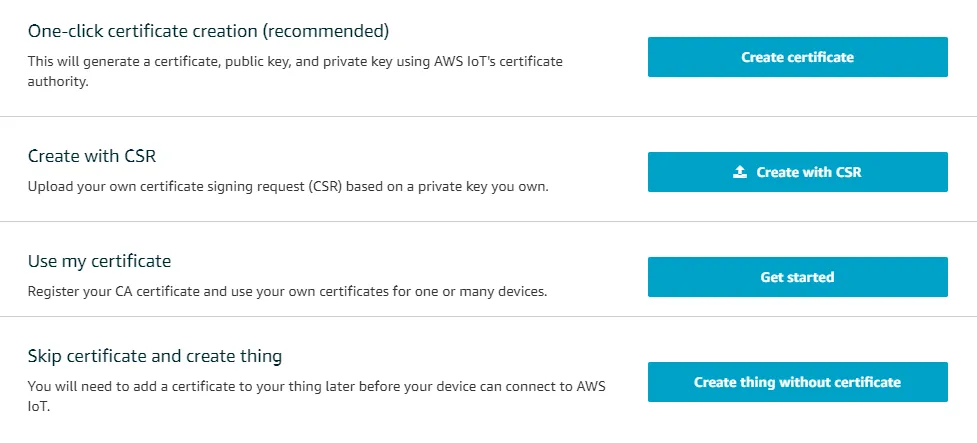

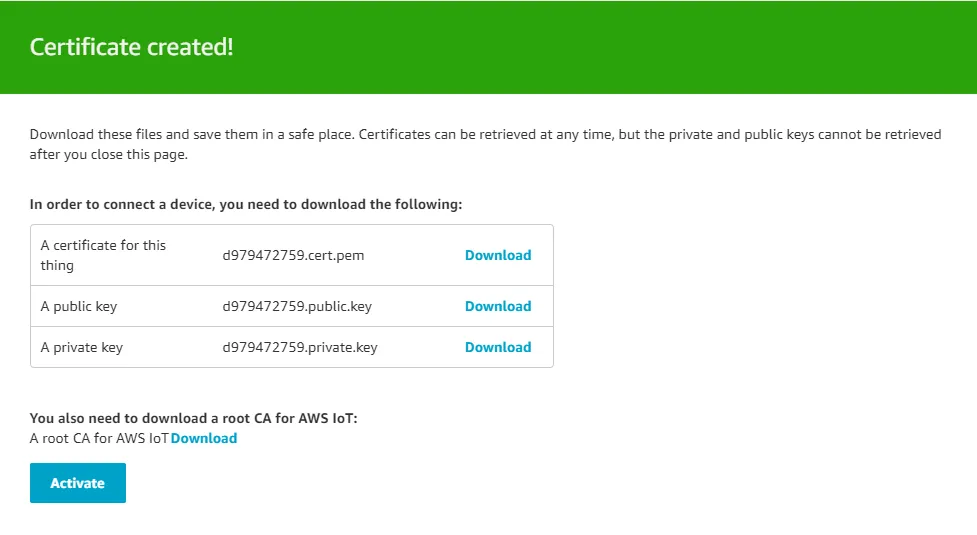

So let’s see how are we gonna implement the system.

{

"Version": "2012-10-17",

"Statement": [

{

"Effect": "Allow",

"Action": "iot:*",

"Resource": "*"

}

]

}

Now we are done with IoT Core setup. We can now proceed to setup our gateway.

We can follow this link

for

setting up raspberry pi.

Once raspberry pi is booted up, we can now start coding our gateway to make it communicate to

PLC and send data to AWS IoT Core.

Lets implement ModbusRead class which will be used to read data from modbus registers:

from pymodbus.client.sync import ModbusSerialClient

import time

import logging

logging.basicConfig(level=logging.ERROR, format='%(asctime)s %(name)s %(levelname)s: %(message)s')

logger = logging.getLogger(__name__)

METHOD = "ascii"

PORT = “/dev/ttyUSB0”

STOPBITS = 1

BYTESIZE = 7

PARITY = 'E'

BAUDRATE = 9600

TIMEOUT = 1

COUNTER = 0

class ModbusRead():

def __init__(self):

self.params = dict(

method=METHOD,

port=PORT,

stopbits=STOPBITS,

bytesize=BYTESIZE,

parity=PARITY,

baudrate=BAUDRATE,

timeout=TIMEOUT

)

self.client = ModbusSerialClient(**self.params)

def connect(self):

try:

self.client.connect()

return True

except:

logger.error("--------No PLC connected-------")

return False

def disconnect(self):

try:

self.client.close()

except:

logger.error("Exception in disconnect Block of Modbus Read code")

def read_reg(self, address, count):

try:

val = ""

val = self.client.read_holding_registers(address, count, unit=0x01)

value = val.registers[0]

return value

except:

return 9999

def get_Register_Values(self, address):

try:

value = self.read_reg(address, 1)

return value

except:

logger.error("Exception Occured in get Registers Value Block")

def put_Register_Value(self, address, value):

try:

self.client.write_register(address, value)

return True

except Exception as e:

logger.error("Exception Occured in Put Registers Value Block")

logger.error(e)

return False

Lets understand above code.

from __future__ import print_function

import sys

import ssl

import time

import datetime

import logging, traceback

import paho.mqtt.client as mqtt

from ModbusRead import *

IoT_protocol_name = "x-amzn-mqtt-ca"

aws_iot_endpoint = "AWS_IoT_ENDPOINT_HERE" # <random>.iot.<region>.amazonaws.com

url = "https://{}".format(aws_iot_endpoint)

ca = "YOUR/ROOT/CA/PATH"

cert = "YOUR/DEVICE/CERT/PATH"

private = "YOUR/DEVICE/KEY/PATH"

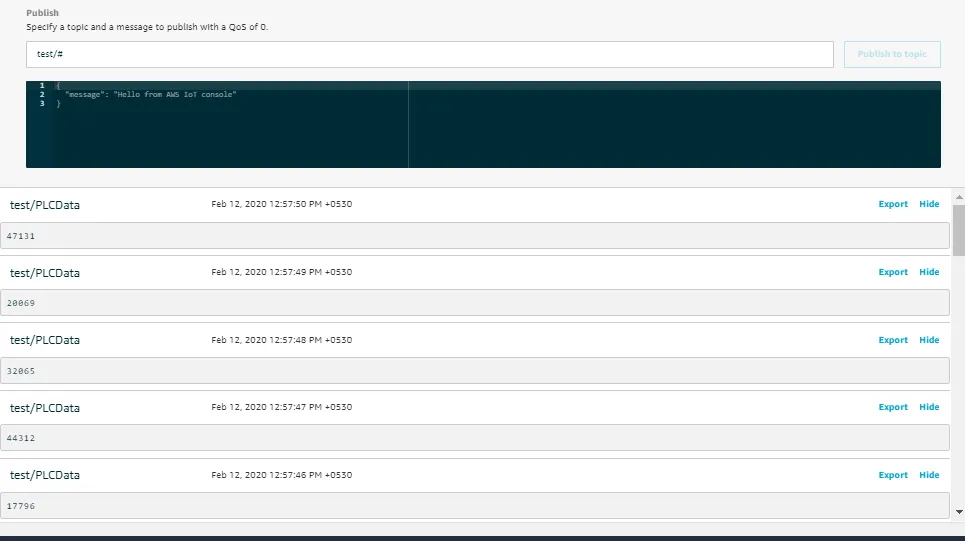

topic = "test/PLCData"

logger = logging.getLogger()

logger.setLevel(logging.DEBUG)

handler = logging.StreamHandler(sys.stdout)

log_format = logging.Formatter('%(asctime)s - %(name)s - %(levelname)s - %(message)s')

handler.setFormatter(log_format)

logger.addHandler(handler)

mbRead = ModbusRead()

mbRead.connect()

def ssl_alpn():

try:

#debug print opnessl version

logger.info("open ssl version:{}".format(ssl.OPENSSL_VERSION))

ssl_context = ssl.create_default_context()

ssl_context.set_alpn_protocols([IoT_protocol_name])

ssl_context.load_verify_locations(cafile=ca)

ssl_context.load_cert_chain(certfile=cert, keyfile=private)

return ssl_context

except Exception as e:

print("exception ssl_alpn()")

raise e

if __name__ == '__main__':

try:

mqttc = mqtt.Client()

ssl_context= ssl_alpn()

mqttc.tls_set_context(context=ssl_context)

logger.info("start connect")

mqttc.connect(aws_iot_endpoint, port=443)

logger.info("connect success")

mqttc.loop_start()

while True:

now = datetime.datetime.now().strftime('%Y-%m-%dT%H:%M:%S')

logger.info("try to publish:{}".format(now))

reg = mbRead.read_reg(2024,1)

mqttc.publish(topic, reg)

time.sleep(1)

except Exception as e:

logger.error("exception main()")

logger.error("e obj:{}".format(vars(e)))

logger.error("message:{}".format(e.message))

traceback.print_exc(file=sys.stdout)

In this post, I’ve shown you how to connect your IoT devices to AWS IoT Core over MQTT on port 443 and sniffing data from PLC. If you have had a constraint in the past to open port 8883 in your corporate firewalls, you can now use a standard port for HTTPS traffic (443) to send your messages over MQTT to AWS IoT Core endpoint.